Tensile Fabric Structures 101: What Are They & What Are Their Uses?

If you have no idea what ‘tensile fabric structure‘ means, then you are not alone! However, it’s highly likely that you have encountered a fabric structure at some point in your life. A tensile fabric structure – also referred to as a tension structure, fabric structure or sail structure – consists of a rigid frame and an outer membrane roof. Tensile fabric structures are characterised by the tensioning of a membrane system, typically with wire or cable. Simply put, it’s a freestanding structure that is capable of spanning vast distances without the need for intermediary supports.

History & Origins

Although tensile architecture is a modern name for it, the origins of fabric structures can be traced back more than 44,000 years to the ice age and the Siberian Steppe, where remains have been found of simple shelters constructed from animal skins draped between sticks and it’s likely these were the first type of shelter constructed by humans. These structures were lightweight and easy to carry which suited our nomadic ancestors.

From purely functional origins, the tent evolved over many centuries to the point where other than for military purposes, fabric structures were used in recreational ways that ran contrary to their roots. It wasn’t until the 1950s that we started to see significant progress in the field as architects exploited the emergence of modern structural engineering to design some truly remarkable structures.

A major pioneer during this time was the late Frei Otto – who proved to be a seminal figure in the development of tensile architecture. Otto realised that structural and architectural forms are inseparable. He argued that flexibility is a strength, not a weakness, and proved that large tensile fabric buildings were possible even though the necessary materials and construction methods were unavailable at the time. The 2015 Pritzker Prize winner’s most highly regarded works include the 1972 Munich Olympic Stadium and the umbrellas that traveled with Pink Floyd on their In the Flesh Tour in 1977.

Another prominent figure that emerged in the 1970s was Horst Berger, a civil engineer. Berger put Frei Otto’s theories into practice, and in 1974, Berger figured out how to mathematically describe and determine the shape of tensioned fabric structures. Berger has also been responsible for some of the most significant tensile structures in the world and can be credited for his role in the build of the roof of the Great Hall at Denver International Airport and the Hajj Terminal at Jeddah Airport.

Modern Day Uses

Fast forward to 2021 and tensile architecture is one of the most promising trends in contemporary architecture. At one end of the scale, you have huge commercial structures such as the Millennium Dome in London and Khan Shatyr Entertainment Center in Kazakhstan that impose on the surrounding area. But there is now a growing demand for smaller tensile fabric structures in schools, hotels and even private homes. There are very few instances where a tensile structure wouldn’t make a great addition to an outdoor space.

Building a Tensile Structure

In most cases, a tensile fabric structure will have no frame with the tensile loads being transferred directly into the foundations or adjoining building. This means that tensile structures require considerable foundations to support the structure – similar to a suspension bridge. The exact size of the foundations will be dependent on the location, and confirmed following calculations for pre-stress, imposed loads, overturning moments, wind suction and downforce by a structural engineer.

In terms of the roof material, most modern tensile fabric structures tend to be formed using PVC coated polyester or PTFE coated glass cloth. Specialist form-finding software is used to set the boundary conditions and geometry of the design to determine the most suitable structural and fabric solution.

The fabric used in tensile structures goes through a stage of pre-tension, where each roll of fabric is tested to the same design loads that the canopy will need to be tensioned to. This process ensures the accuracy of the design and minimises the risk of ponding on the canopy.

PVC coated polyester offers 15-20 years of use although the expected lifespan is reduced in particularly sunny locations. PTFE coated glass cloth is an alternative for specifications of a stronger fabric and durability – which can be up to 50 years, and also benefits from being self-cleaning. However, it’s considerably more expensive than PVC fabric.

There are now less common materials available such as silicone coated glass and ETFE foil. All of these architectural fabrics are available in a wide range of colours, strengths and translucencies.

Fabric structures are generally given their structural stability by double curvature. This may be:

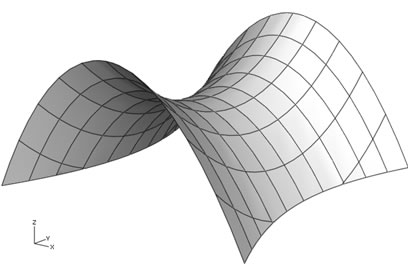

- Anticlastic (saddle shaped), where the two axes of the fabric curve in opposite directions.

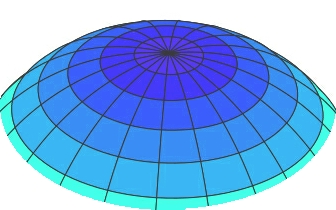

- Synclastic (dome shaped), where the two axis of the fabric curve in the same direction.

In structures with an anticlastic shape, cables at the edge of the fabric are pulled into tension, whereas synclastic shapes are usually formed by internal air pressure.

Anticlastic

Synclastic

The reason tensile structures are given shape is that large flat pieces of fabric are very poor at resisting loads and will quickly start to sag. Without sufficient curvature on the canopy, the structure would not be capable of coping with rain and snow loads and also wind uplift. This is where we arrive at the three main fabric styles: the hypar, cone and barrel vault.

Advantages Of Tensile Fabric Structures

- Tensile structures don’t use the same rigid intermediate support that other structures require, meaning it’s possible to cover significant distances without intermediary columns. This makes them ideal for covering sports pitches, performance areas and shopping centres to name just a few.

- Their superior strength and resistance to adverse weather conditions makes them a permanent solution.

- In addition to their practicality, fabric structures can add a touch of elegance and beauty to any outdoor space.

- There is minimal ongoing maintenace required and a bi-annual or annual clean should be sufficient to keep a structure in top condition.

- There are many possible styles, shapes and colours that can be adapted to suit individual specifications.

How Do Tensile Fabric Structures Compare To Alternatives?

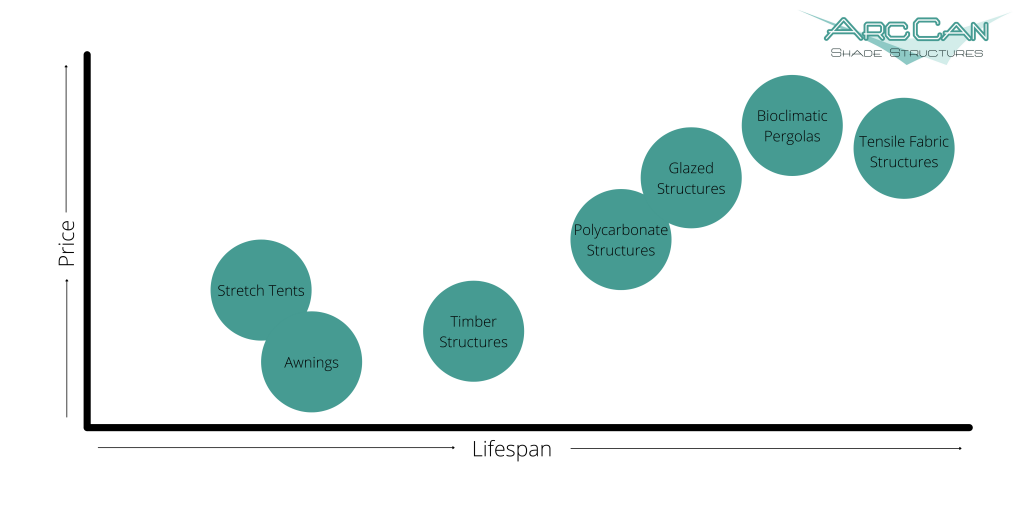

There are so many different ways of covering an outdoor space that it’s important to make the best decision based on the project requirement. For example, a shade sail is great for customers that want some sun protection and something with a bit of style, but wouldn’t be the most suitable choice if looking for an all-weather canopy.

Similarly, it’s important to compare the upfront cost of a shade structure in addition to the lifespan to determine the true value. This isn’t to say that lower cost shading options shouldn’t be considered – there are times when a stretch tent may be most suitable if the application is for a temporary event, an awning is a practical when it’s not possible to have any posts or to comply with planning.

Enjoyed this post?

Sign up to our mailing to receive similar insights.